With our pilot and pre-series moulds, risks for the series process can be minimised and higher quantities can be produced close to series. If desired, the cavities can be used as a replacement for a later production tool.

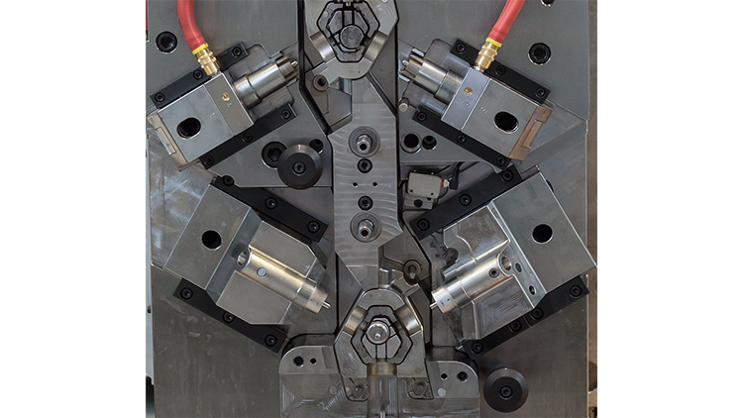

Stable mould concepts, highest precision, guaranteed interchangeability of cavities and high mould availability characterise our moulds.

Regardless of the number of compartments, number of components and transfer technology, such as core baking, turntable, cube, indexing cross or vertical turning unit, we develop innovative mould concepts for our customers.

For components with the highest optical or technical demands, such as high-gloss surfaces or thin-walled areas, we build specially heated cavities into our fischer tools.